Digital printing is one of the most important achievements in the history of printing in the 20th century. Low printing costs, even for very small print runs, and individual content on each page are the most important advantages that could be achieved. But how did the invention of digital printing actually come about? We followed the story and found out some interesting facts.

The history of the printing process

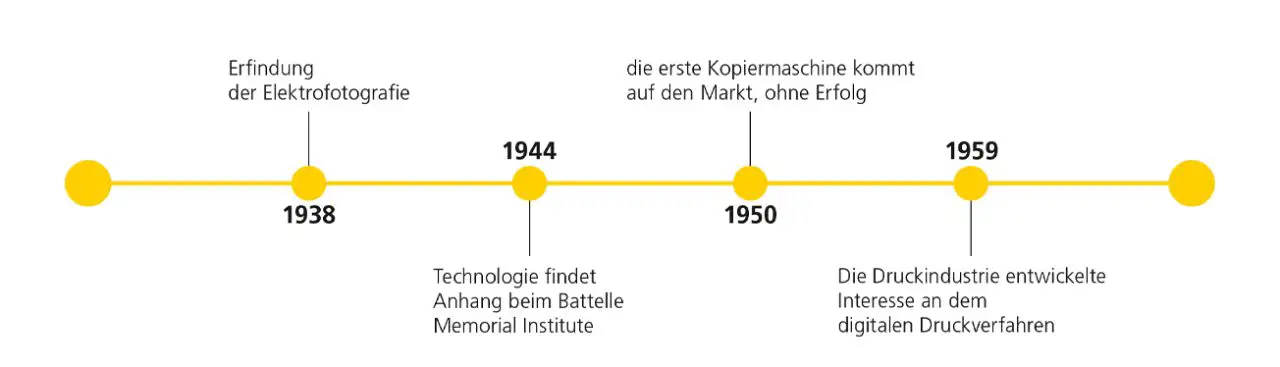

The emergence of digital printing dates back to the 1930s. Below is a brief journey through time in pictures and text:

In 1938, Chester F. Charlston laid the foundations for the future with the invention of electrophotography, also known as xerophotography.

of the method. However, the technology only found its first acceptance some time later, at the American Battelle Memorial Institute for Contract Research in 1944 to be precise.

In 1950, the first copying machine was launched on the market, which was also based on the new technology – but the desired success did not materialize.

Around 10 years later, the printing industry also developed an interest in the digital printing process. Published in 1959, the

“Model 914”, a printer weighing over 300 kg, sparked so much interest that around 200,000 units were produced by the 1970s.

Over the course of time, the machine and technology were improved so that they could establish themselves in everyday use.

How does the digital printing process work?

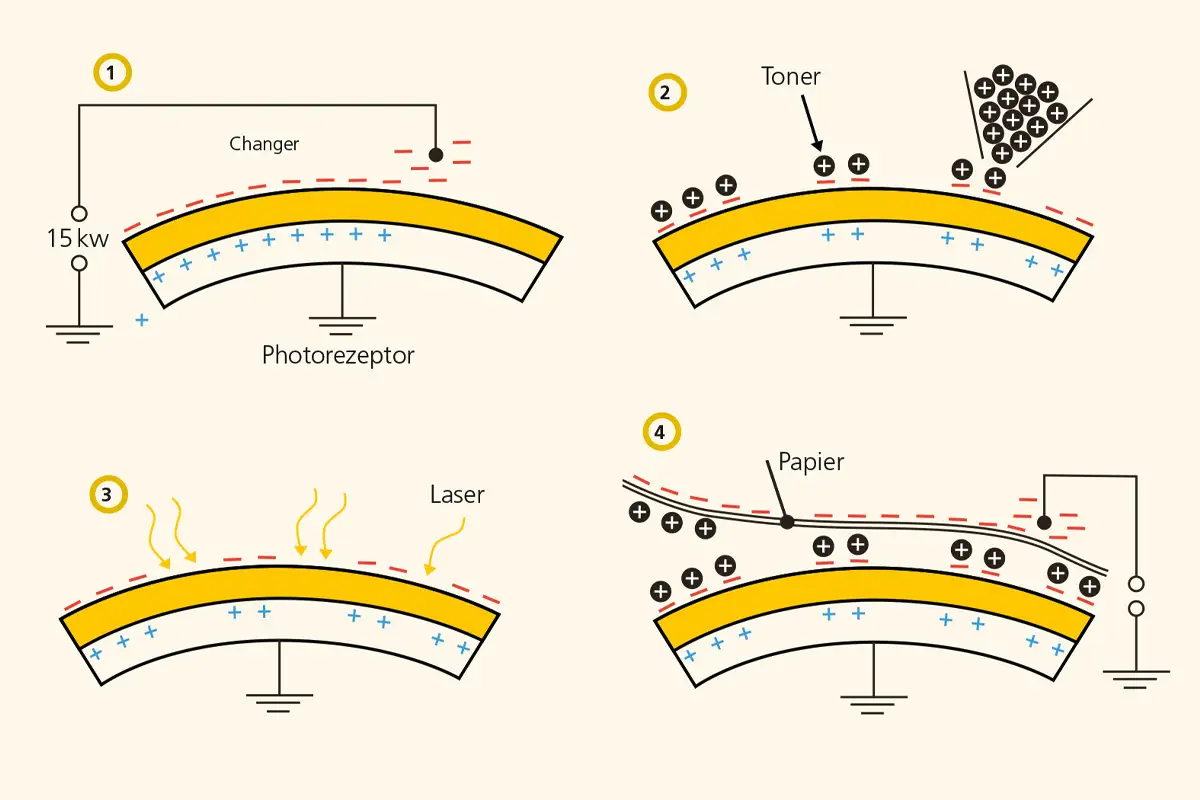

While offset printing works on the principle of water and grease, digital printing uses electrical charges. The individual steps of the process are visualized in the graphics below.

The complete procedure:

Ionization of the photoreceptor produces a negative charge.

The areas where the ink (toner) is not to be applied are discharged using a laser beam.

The positively charged toner only adheres to the negatively charged areas of the photoreceptor.

An inverted image is created there.

The paper is given a negative charge and the positively charged toner is absorbed by the printing material.

Now a sideways image is formed.

Oil, pressure and high heat (up to over 200° C) are required to fix the toner ink to the paper:

A heated roller ensures that the ink adheres to the respective printing material by melting it.

Note: The printing oil only serves as a separating layer to ensure that the toner is transferred to the substrate and does not adhere to the roller.

Digital printing – what’s behind it

We don’t want to make things too complicated: The term “digital printing” refers to all printing processes that apply the printed image to the substrate without a static or fixed printing form. In contrast to offset printing, no fixed artwork is required. A particular advantage is that each sheet can be printed individually. Incidentally, most of the printers we use privately also work according to this principle.

The advantages of digital printing

- Flexibility: Small print runs can be realized easily.

- Short production time: The products are usually printed within hours or a few days.

- Individuality: There are no limits to the personalization of the desired product, such as business cards, flyers, personalized invitations, books, catalogs, direct mailing campaigns, etc.

- High quality: Consistent print and color quality are guaranteed and are checked daily and adjusted if necessary.

- Cost-effective: Digital printing is particularly cost-effective for small production quantities or individualized products.

an optimal price-performance ratio.

Digital hub on Binzstrasse

We took our first steps with high-performance digital printing, and our starting signal for a future-oriented production method, back in 1994 when we decided on the first DocuTech series – 135 A4 pages printed in black and white in one minute!

This fascinating technology has not let us go and just one year later we added a second printing press with the same system.

After digital color printing made great qualitative progress towards the end of the 1990s, we also decided to enter the world of digital color printing at the beginning of the new millennium, which proved to be a logical step.

Options such as a wide variety of substrates (e.g. textured and synthetic papers, pre-prints of all kinds, carbonless paper), long formats, various inline stitching, inline completeness checks, consistently high quality, personalization and much more have become commonplace and solve both simple and complex tasks

of our customers.

Today, we have two high-performance printing systems for the black and white sector (around 7 million prints per year) and two for our color volume (around 1.5 million prints per year) – capacities in our formats that are unparalleled in the Zurich economic area. After printing is before finishing, and we do over 90 percent of this in-house. Our equipment professionals crease, fold, punch, staple, perfect bind, pack by machine or by hand and ensure that your products arrive in the specified quantity, at the right place and at the right time or are even handed over personally – Digital Hub made in Zurich!

Data sources: www.drucks.ch / www.gutenbergblog.de